Telelift in the industry - Interview with Hartmut Tröger

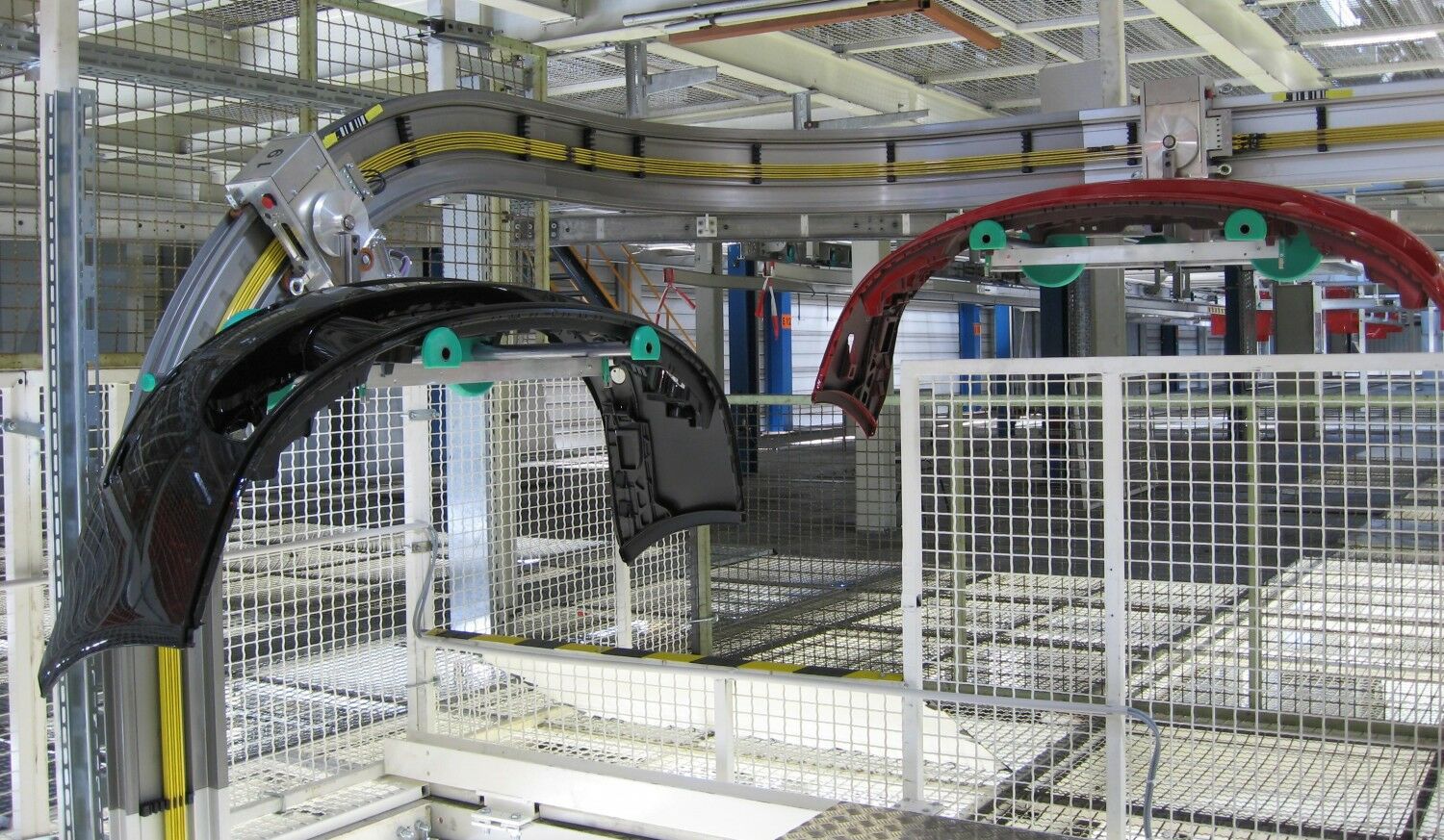

Modern production sites and modular manufacturing structures are optimally supported by overhead, rail-bound conveyor systems from Telelift.

Transport goods are transported overhead to production machines or machine operators without media breaks. The solution is tailored to the customer's individual requirements.

In an interview, Hartmut Tröger, Director Sales & Service, explains why Telelift's industrial solution is so well received by customers.

Mr. Tröger, as Director Sales and Service, you also look after our industrial customers. Why do you find that so appealing?

No two industrial applications are the same. Working with industrial customers from a wide range of industries gives you an insight into a wide variety of production, assembly, and process flows. From food and micro fulfillment centers to automotive and high-security applications in the nuclear industry, we've seen it all.

What I enjoy most is transferring knowledge and experience from one project or industry to another and thus thinking outside the box in order to develop the right solution together with the customer.

Basically, in my opinion, there is no general solution, but it is important to find out how best to meet the individual requirements of the customer.

That sounds exciting, where do you see the difference of the Telelift system compared to the competition?

Here, it should be differentiated in which reference the differences are to be understood. From a technical point of view, we differ fundamentally because our rail-bound systems can map both horizontal and vertical transports. A transfer between two transport systems often involves a certain potential for error. This is not the case with the Telelift MultiCar and UniCar, which our customers greatly appreciate.

Therefore, it is always necessary to find out for which requirement and which project the advantages of the Telelift MultiCar outweigh alternative solutions. In some projects, it can be very useful to combine different technologies in order to create an overall solution that is suitable for the customer.

In general, it is a matter of developing those solutions through the right communication with the customer that bring the most benefits compared to an alternative solution.

Hartmut Tröger, Director Sales & Service

The Telelift solution is very flexible and individual. Where do you see the main advantages?

As already explained, different systems have different characteristics. Therefore, the advantages cannot necessarily be considered in a generalized way. However, the main strengths of the Telelift MultiCar should be emphasized:

- A wide range of different load handling devices (passive as well as active)

- Floor-free conveying and the associated process reliability

- The possibility of 3-dimensional layout design with minimum line load

- Scalability

- Minimum space requirement

- Minimal requirements for the structural conditions

- No media breaks (no transfer between individual elements such as horizontal and vertical conveyors, which minimizes the sources of errors)

Are there also limitations with the Telelift solution for industry?

Like every system, the Telelift MultiCar also has physical limits, such as the payload in combination with the selected load handling device. The maximum payload is essentially dependent on the cubature as well as the center of gravity of the load.

That all sounds very good. Where has the Telelift MultiCar system already been used?

The Telelift MultiCar is already being used in a wide variety of applications. For example, we transport door panels or body parts in the automotive industry. In solar technology, sensitive electrical components are transported. In the food industry, the MultiCar supplies beverage filling plants. Even laboratory samples and medicines are transported gently with the MultiCar.

In addition, another project in the high-security area is currently in the planning and test phase.

In addition, all products that fit into a 600 mm x 400 mm box can be transported. Basically, the Telelift MultiCar is not bound to any industry. We develop an individual solution together with the customer.

Mr. Tröger, do you have any advice for your customers on what to consider during planning?

There are many factors to consider when planning a project. Therefore, our offer for all interested parties: We are happy to take time, discuss the requirements and create a common understanding of the task.

On this basis, we create and present an initial concept. This concept can then be adapted and optimized together if necessary. We have repeatedly found that the path to the optimal solution is a dynamic process together with the customer.

Mr. Tröger, thank you very much for the interview!