Telelift MultiCar – Lots of functions, just one technology

The MultiCar has been specially developed for use in industry. It enables customised, flexible solutions for almost all types of transported goods. Due to the use of various load-carrying attachments, components and many other things can be sent exactly where they’re needed.

With the aid of modular rail technology, the MultiCar conveys goods in even the tightest spaces, and in all directions, horizontally or vertically. The MultiCar system’s flexibility enables it to be adapted to new processes, easily and without complications. Different conveying systems are therefore no longer necessary for different production processes.

Small number of components – One system

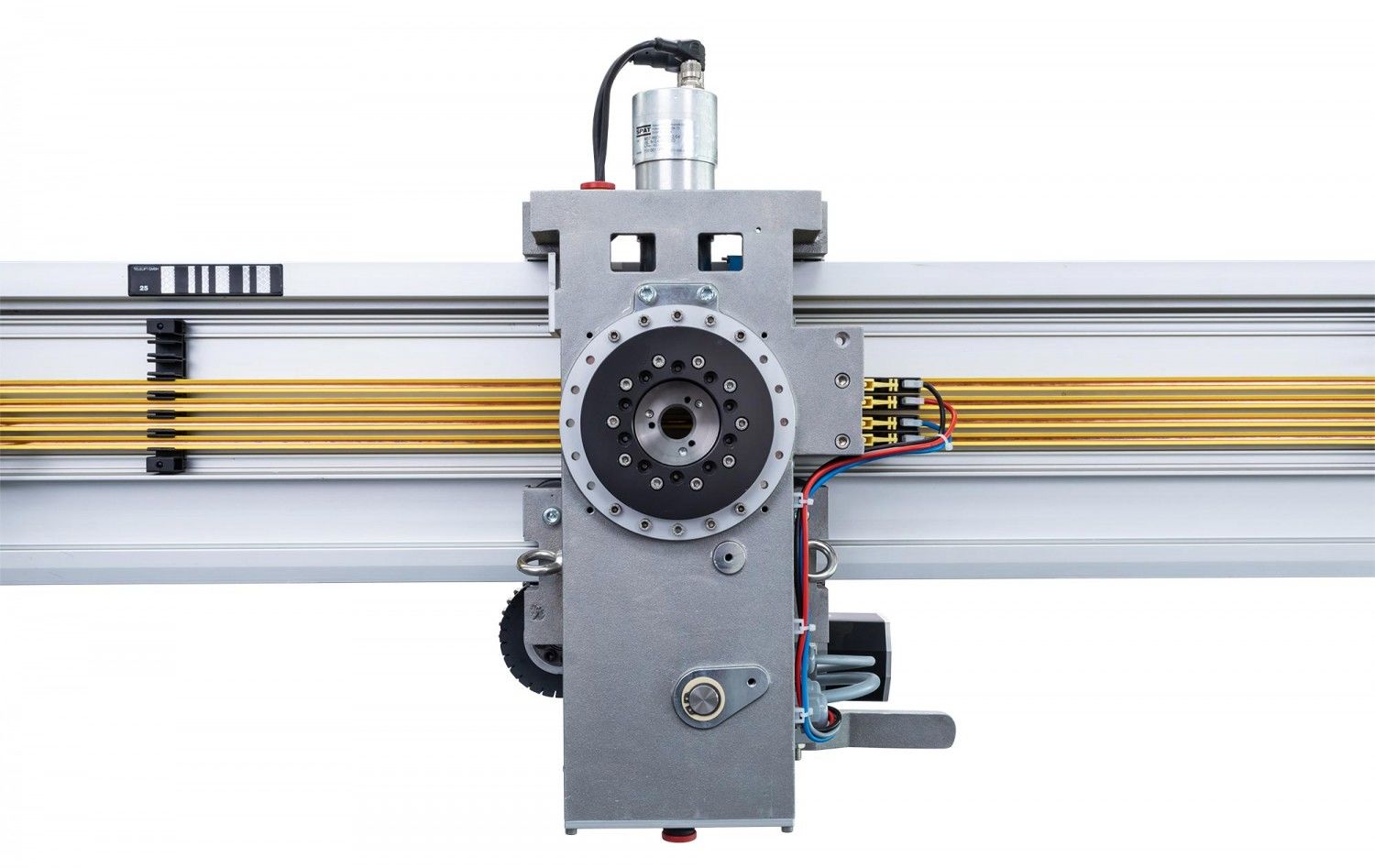

MultiCar chassis

The standard chassis can be combined with a number of customised load-carrying attachments, in order to cover all customer applications. Regulated, brushless drives ensure configurable transport speeds in both transport directions, and precise positioning in the loading and unloading area.

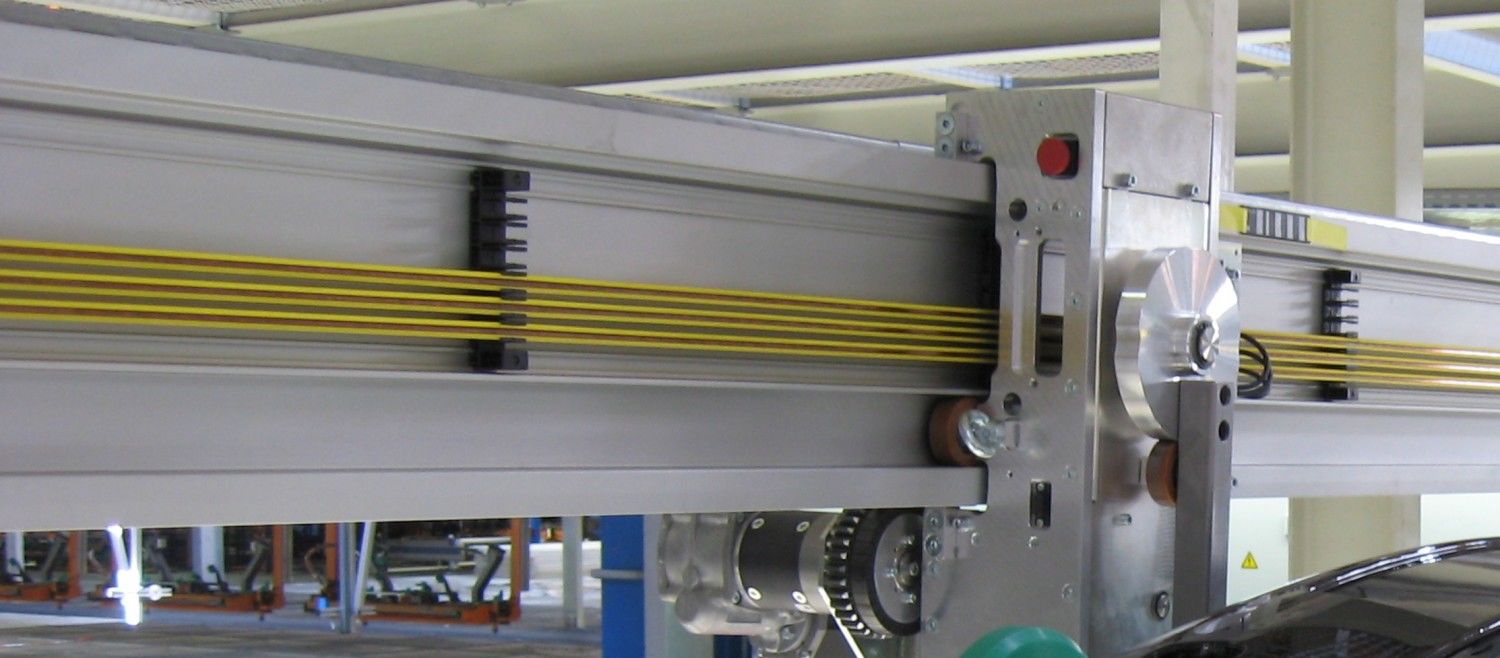

MultiCar rail

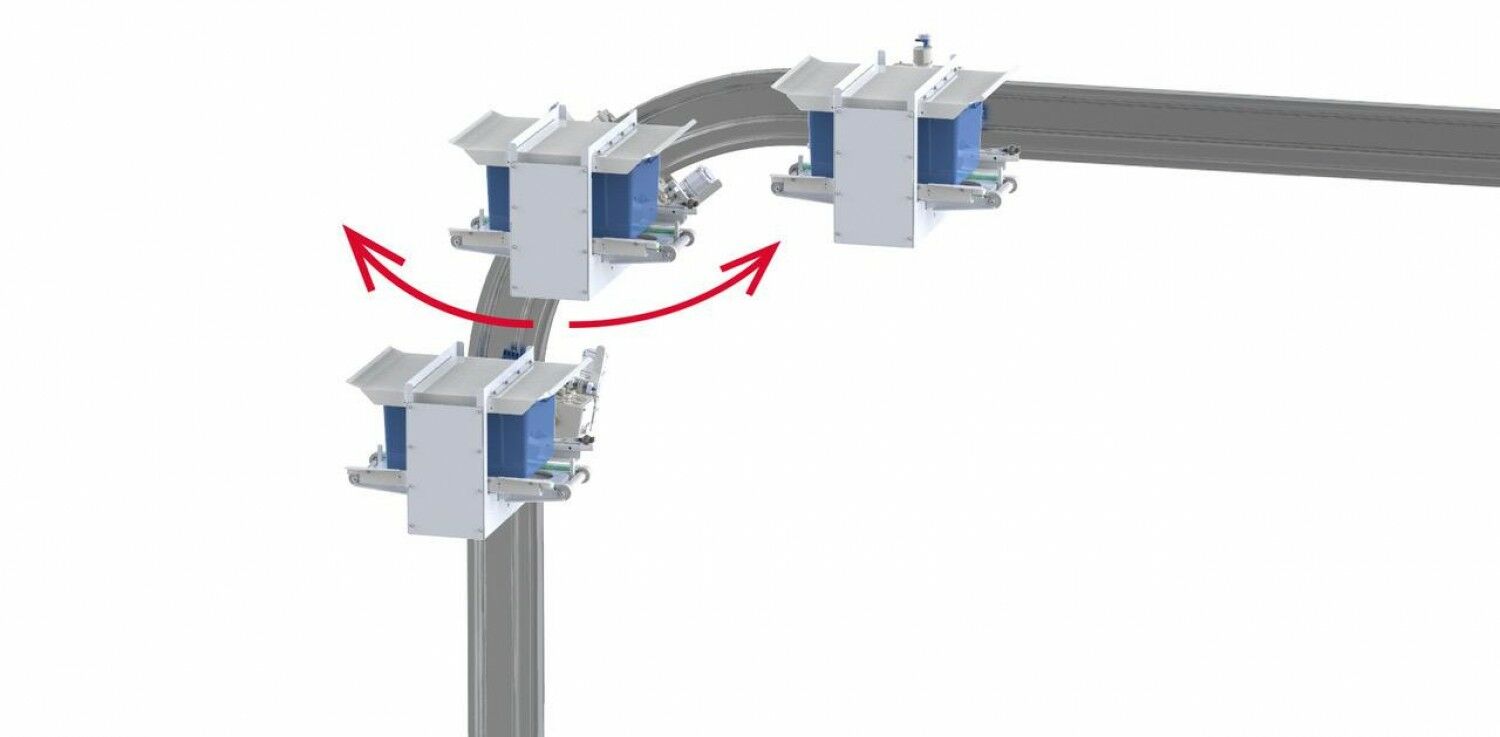

Thanks to the rail system’s modular design, virtually all transport routes can be realised. Straight rail elements, curves for horizontal changes of direction and bends for vertical changes of direction make the MultiCar system highly flexible.

In combination with points, material flows can be distributed to multiple places or brought together in one place.

MultiCar control system

The decentralised, PLC-based Telelift TeleControl control system controls the transport jobs, as well as taking care of system monitoring and visualisation.

The control systems communicate via a TCP/IP network, with characteristic communication occurring via a communication rail installed in the rail profile.

System analyses can be carried out via the central visualisation, individual operator terminals or using service laptops.

Upon request, the TeleControl control system can be integrated into the customer’s own control system and monitoring peripherals (connection to MES or ERP system, head control).

Design of the load-carrying attachments tailored to meet customer requirements

Depending on the transport task that needs to be accomplished, custom design of an individual load-carrying device is usually required. Depending on the form, route and goods to be transported, there are fundamentally three different methods of connecting the load-carrying device:

Rigid connection:

The load-carrying attachment is fixed directly to the chassis, meaning that no relative movement is possible. When travelling along bends, the load-carrying attachment does not therefore rotate.

Rigid load-carrying attachments are particularly suitable for purely horizontal or vertical transport.

Characteristics: Greatest load capacity, transport in closed boxes

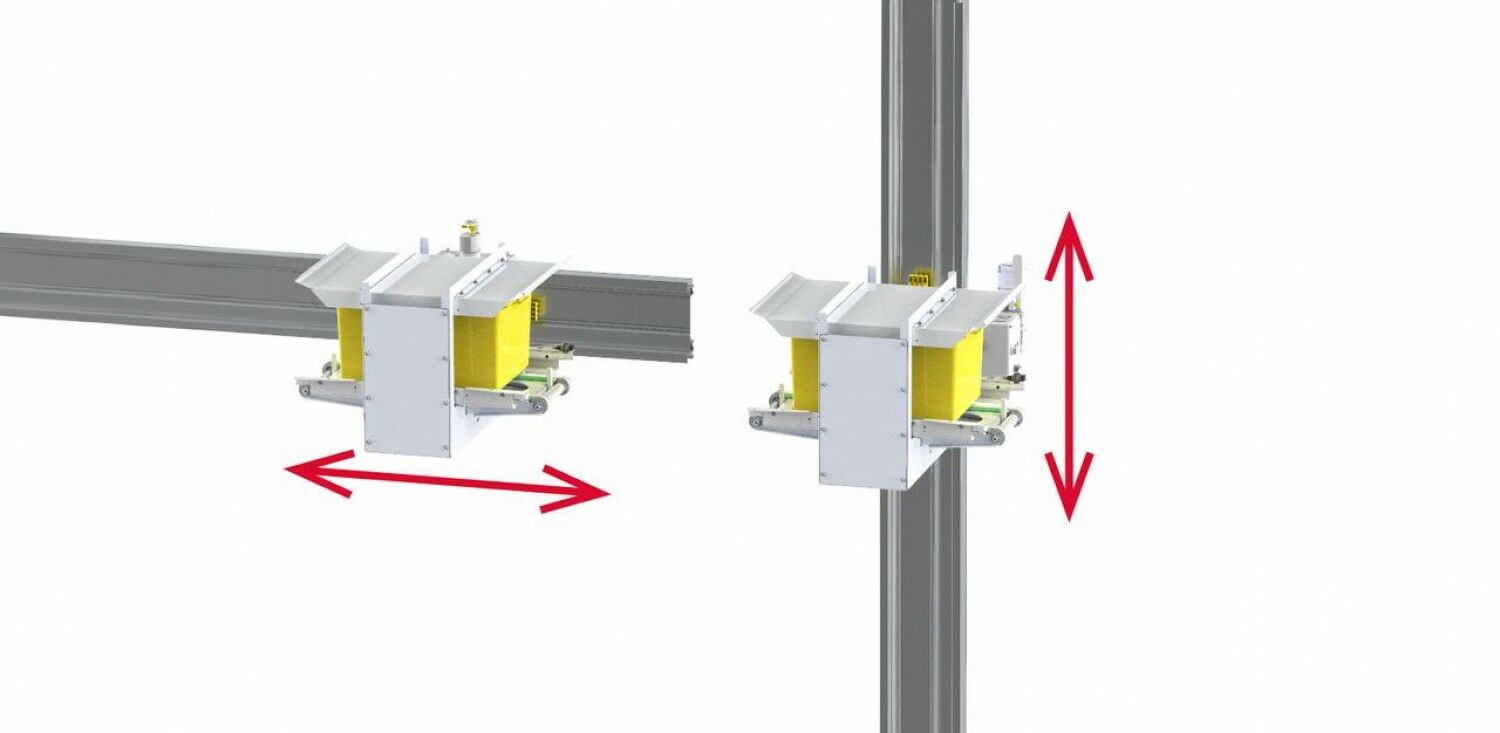

Gravity-controlled connection:

The load-carrying attachment is connected to the base chassis by means of a freely rotatable flange with bearing. Due to the goods being transported having a lower centre of gravity than the bearing point, the position corrects itself on the basis of gravity, therefore enabling gentle transport.

Rotatable load-carrying attachments with bearings are particularly suitable for suspended transport.

Characteristics: Medium load capacity, gentle transport

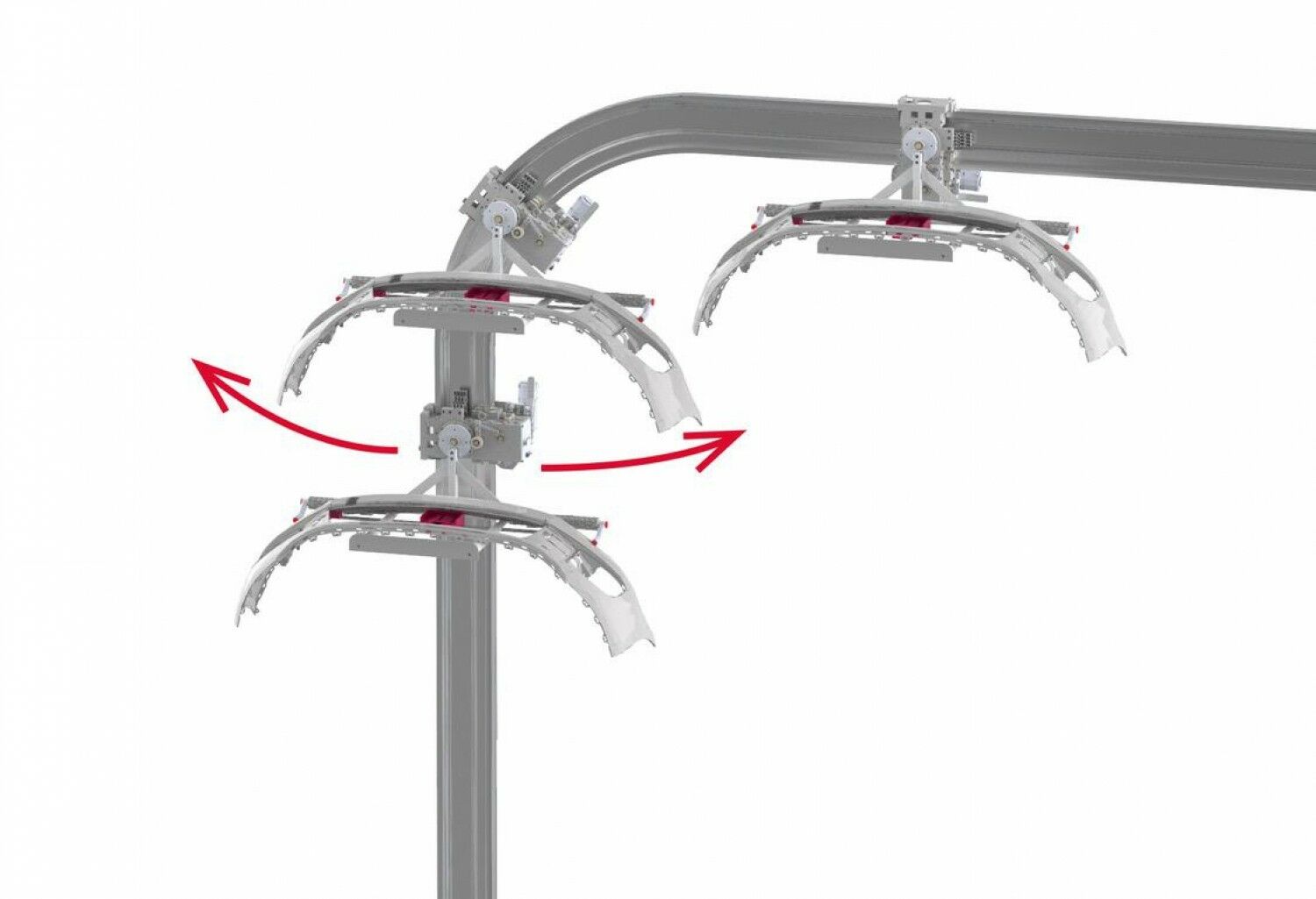

Actively controlled connection:

The load-bearing attachment is connected to the chassis by means of a rotatable flange with bearing, which in turn can be actively turned via a separate drive and a bevel gear. The direction is actively regulated and controlled by a position control drive. In basic functionality, this therefore ensures angle compensation when moving along bends, so that the load-carrying attachment is always kept horizontal. Optionally, the load-carrying attachment can also be actively turned at certain positions. Compared to the gravity-controlled connection, more compact envelope curves are achieved, because no eccentricity is required between the axis of rotation and centre of gravity.

Characteristics: Lower load capacity, gentle transport, smaller envelope curves, additional function due to active positioning of the load-bearing attachment.