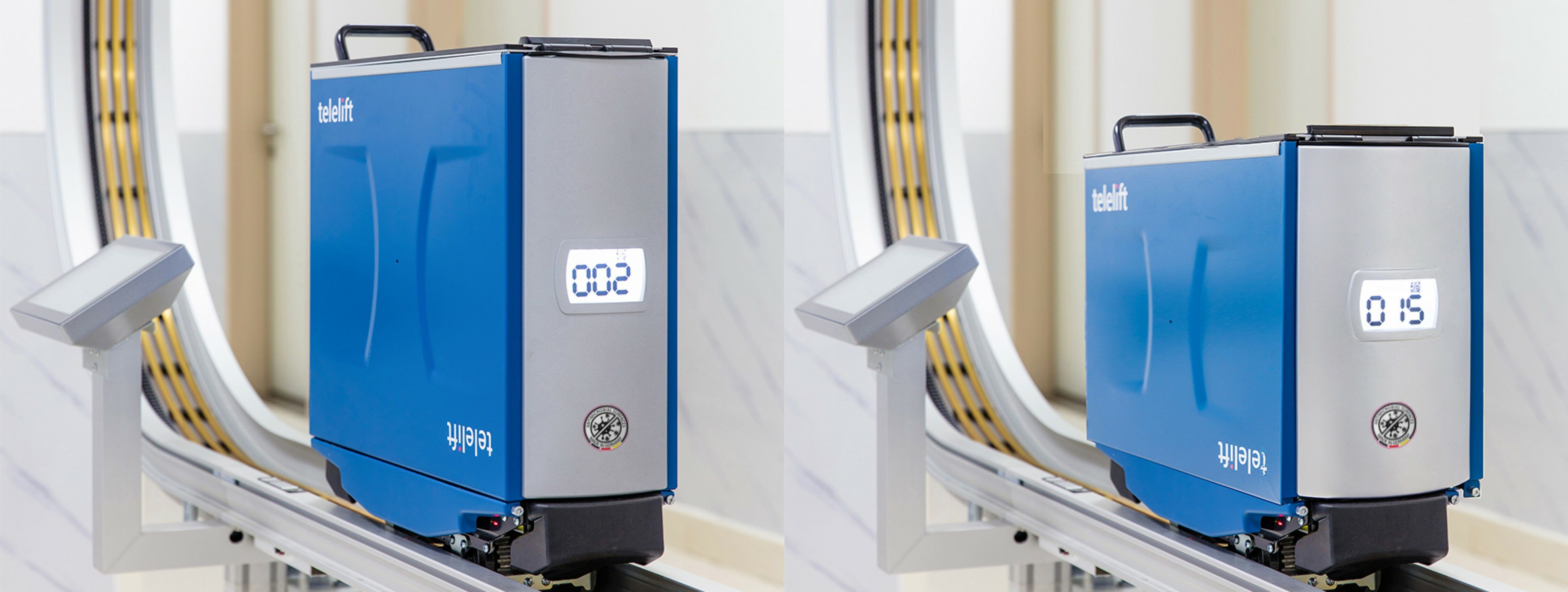

UniCar closed – Trolley models UniMedCar10 and UniMedCar15 for hospital transport

Trolley models UniMedCar10 and 15 have been specially developed for transport duties within hospitals.

They are the perfect solution for quick, reliable transport between operating theatres, pharmacies, laboratories, storage areas and nursing stations in hospitals.

The secure, locked and electronically monitored transport containers guarantee hygienic, secure transport from the pickup point to the destination, with complete transport documentation. The TeleControl transport job management system ensures that the transport jobs are processed quickly via the shortest possible route.

In hospitals, the UniMedCar takes care of transport logistics for:

- Medication (single and consolidated transport possible)

- Infusions

- Blood and urine samples

- Tissue samples (single and consolidated transport possible)

- Blood reserves and plasma

- Vaccines

- Sterile items

UniMedCar10:

- Load capacity up to 10kg

- Vehicle width: 185mm (internal dimensions)

- Transport volume: approx 38 litres

- Max. speed: 0,5 m/s horizontal

- Narrow conveying containers to take up the least amount of space in buildings (narrower distance between rails, narrow points and fire doors)

- Antimicrobial surface coating

- Optional with internal swivel box

- Electronic lid closure

- Safety buffer as contact protection

UniMedCar15:

- Load capacity up to 15kg

- Vehicle width: 234mm (internal dimensions)

- Transport volume: approx 37 litres

- Max. speed: 0,8 m/s horizontal

- Lower (but narrower) conveying containers for more ergonomic manual loading and unloading.

- Optional: UV-C-Disinfection

- Energy efficiency

- Robust Design

- Dynamic and static speed monitoring

- Increased safety and stability

- Overload safety due to temperature-monitored drive

- Integrated overvoltage protection

- Optional with internal swivel box

All UniCar vehicles used for hospital transport offer the following features:

Antimicrobial design

The Telelift UniCar system has been designed so that it is ideally suited for use in hygienically demanding hospital environments. It has an antimicrobial surface coating that prevents the growth and spread of most bacteria and germs over a long period of time. It thus contributes to a sustainable, hygienic overall solution in the hospital.

Electronic lid locking

The electronic lid locking system protects the items being transported against unauthorized removal during transport, only allowing the containers to be opened at the intended destination.

Access-protected transport (optional)

In conjunction with the station terminals (modern 10.1" touch screens), the electronic lid monitoring system also optionally makes it possible to access-protect the goods being transported (for example expensive medicines or items subject to strict regulations) by entering a PIN code when sending and receiving them at the station. (This option is part of the standard TeleControl delivery.)

As an additional option, it is also possible for personnel to identify themselves at the stations, for example using an RFID card.

Vehicle ID

Each vehicle is fitted with a permanent identification number. This enables continuous monitoring of all transport jobs, as well as of the vehicle’s maintenance status. In conjunction with personal PIN coding during loading and unloading, complete monitoring of all transport jobs is achieved.

Self-aligning base (optional)

It is possible to fit a self-aligning base in the conveying container. This always guarantees horizontal – and therefore gentle – transport of for example liquids or sensitive items, even when being transported vertically or overhead.

One-handed operation

The new, one-handed vehicle operation makes handling even easier for personnel, and also minimizes the need for set-down areas.